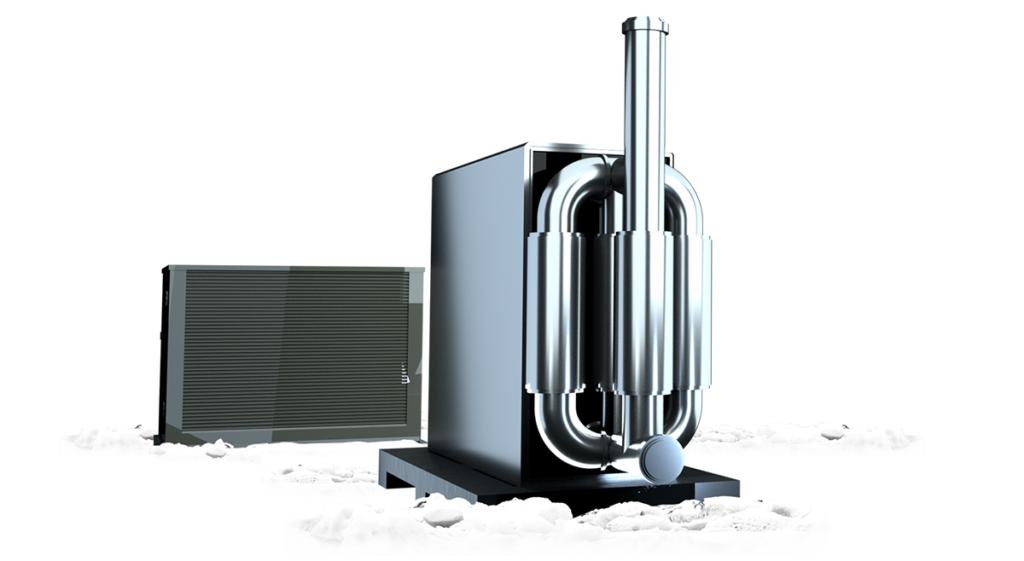

Ethanol Chilling systems

The undisputed champion of ethanol process chilling just got upgraded. The 2022 BLAST™ series has been built from the ground up, with every upgrade based on hundreds of thousands of run time hours, processing millions of lb’s of biomass. Ditch the liquid nitrogen and save on consumables.

See Our Ethanol Chillers