The Rise of Direct Ethanol Chillers

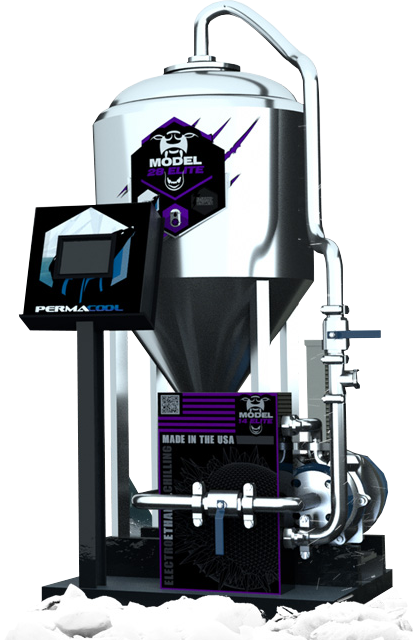

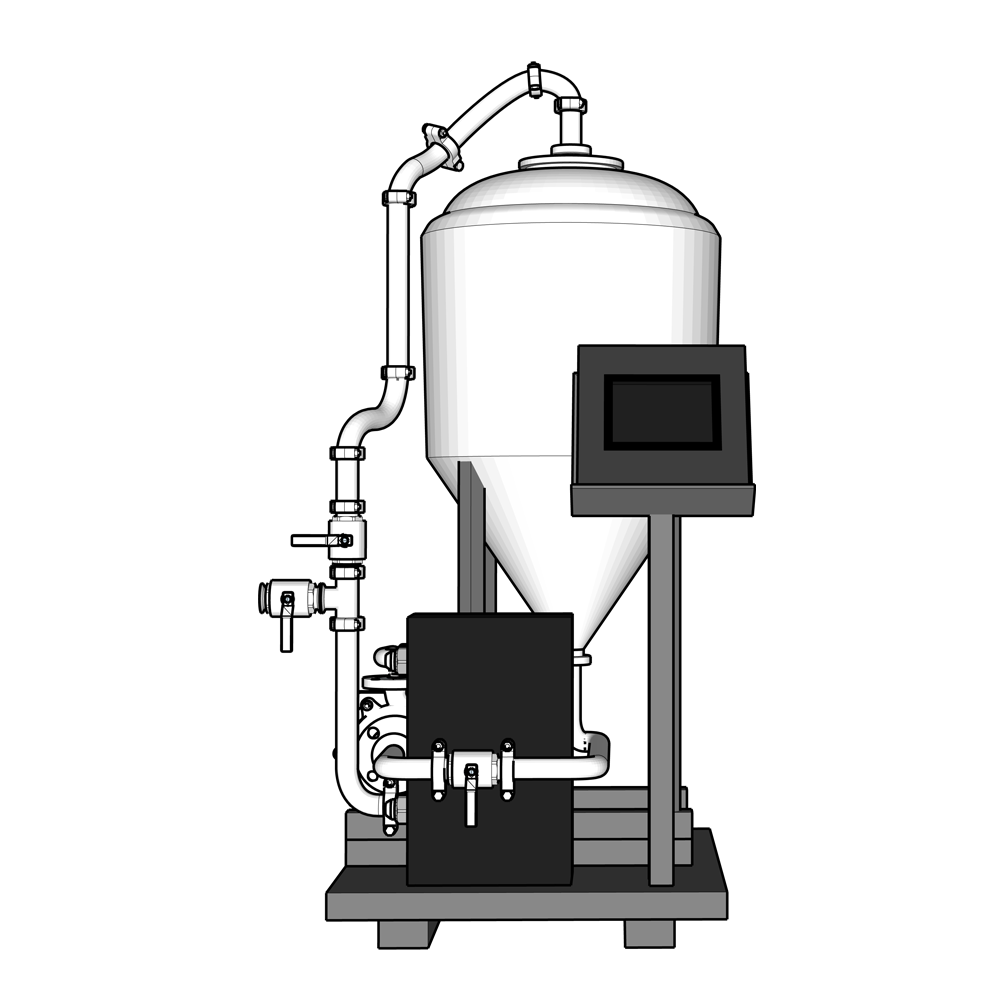

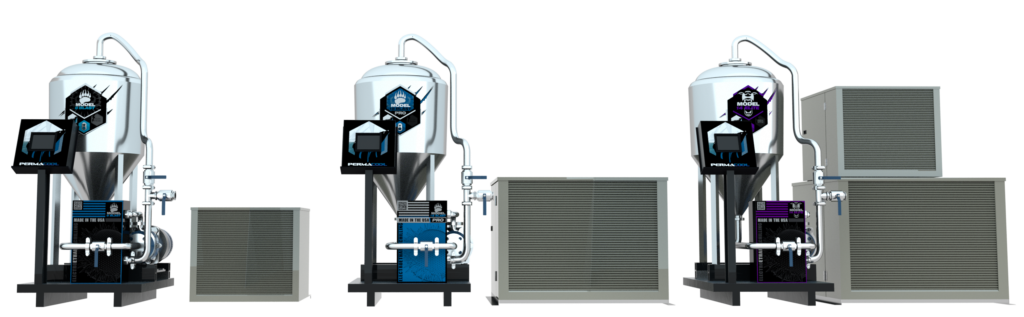

The original Direct Ethanol Chillers, known for their efficacy and reliability, have returned to the market. But this time, they’ve undergone a significant transformation. These NEW upgraded models, tailored specifically for the botanical plant extraction industry, are a result of tireless refinements drawn from countless hours of field operations. The BLAST™ line of chillers epitomizes this evolution. By reallocating investments to enhance horsepower, these chillers are a testament to where innovation meets efficiency.

These chillers are not just machines; they are meticulously designed systems that offer users substantial savings in time, space, and capital. By employing an HVAC Condenser, they streamline the cooling process, reducing unnecessary complexities and overheads.

Liquid Nitrogen: A Costly Affair

Liquid Nitrogen, or LN2, has been a staple in the extraction industry for some time. Praised for its rapid cooling capabilities, it’s easy to see why it became a favored choice. However, beneath the immediate advantages lurks a significant financial implication.

To put things into perspective, consider a hypothetical scenario where an extraction facility spends $25,000 each month solely on procuring LN2. This translates to a staggering $300,000 annually, just on a consumable. It’s not just about the upfront cost; it’s the recurring financial burden month after month, year after year.

HVAC Condenser: A Sustainable Alternative

Now, juxtapose the LN2 expenses with the operational costs of running an Electric Ethanol Chiller integrated with an HVAC Condenser for a month. Firstly, an HVAC Condenser, as a direct chilling system, eradicates the need for consumables. The primary expenses are limited to electricity and periodic maintenance. Over a year, the difference in operational costs between LN2 and an HVAC Condenser can be monumental.

Moreover, direct chilling systems with HVAC Condensers are not just about cost savings. They exemplify efficiency. By leveraging the ambient air or water, they cool the ethanol directly, reducing the cooling time and ensuring a more consistent temperature throughout the extraction process.

In Conclusion: The Future of Cooling in Botanical Plant Extraction

In an industry as dynamic as botanical plant extraction, technological decisions directly influence profitability. While LN2 based systems have had their time in the limelight, the economic and operational realities today underscore a pivotal shift towards Electric Ethanol Chillers with HVAC Condensers.

The BLAST™ line of chillers is a testament to this evolution. They represent not just machines, but a philosophy – one that emphasizes efficiency, sustainability, and cost-effectiveness. As the industry continues to grow, those looking to stay ahead of the curve will find a reliable partner in these state-of-the-art direct chilling systems.

By making a conscious switch from LN2 to HVAC-integrated Electric Ethanol Chillers, businesses stand to gain not just in immediate savings, but in long-term operational excellence and sustainability.

Perma Cool Blast Ethanol Chillers