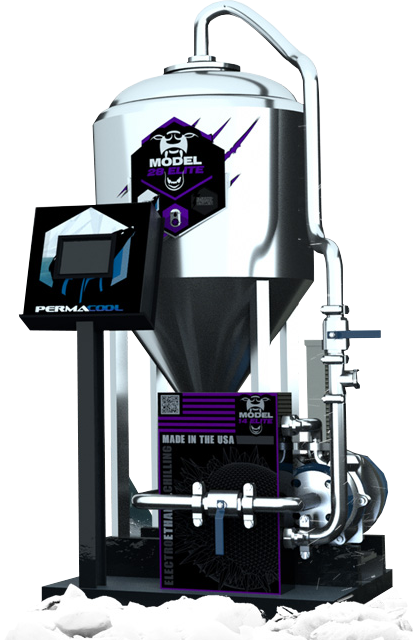

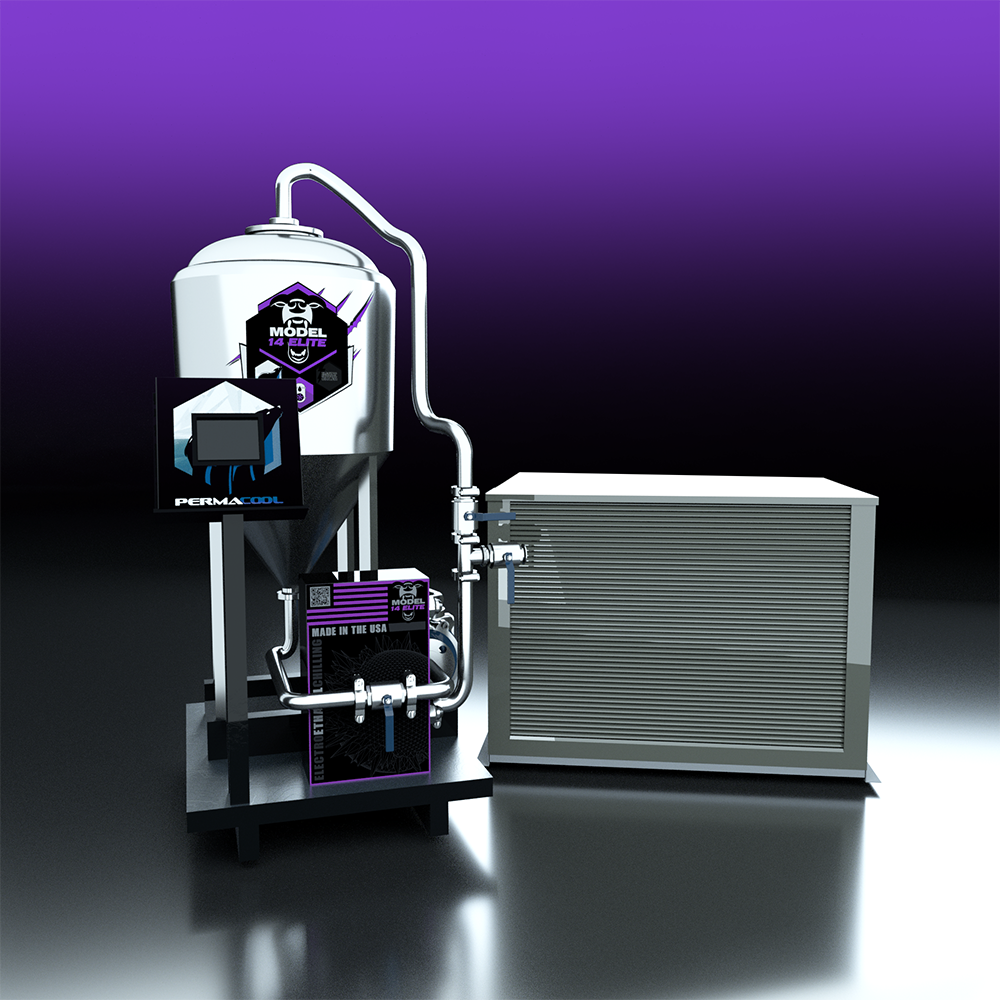

Ethanol Chiller(s) No Liquid Nitrogen Required

The botanical plant extraction industry is witnessing a paradigm shift with the introduction of advanced Electric Ethanol Chillers, especially when integrated with a standard HVAC Condensor. These chillers, a notable advancement from the Direct Ethanol Chillers, have been meticulously engineered to cater to the industry’s specific needs. The BLAST™ line, in particular, showcases the pinnacle of efficiency, optimizing both time and space. The core selling point, however, remains the stark difference between the Ethanol Chiller’s operational cost and those relying on Liquid Nitrogen (LN2) for cooling. LN2, despite its effectiveness, carries a high and continuous expense.

Choosing an Ethanol Chiller with an HVAC Condensor promises not just robust cooling but also significant financial savings. This is because, unlike LN2-based systems, Electric Ethanol Chillers reduce recurring costs, providing a sustainable and economically viable solution. For those prioritizing both efficiency and affordability in the ever-evolving extraction industry, the Electric Ethanol Chiller stands out as the clear choice. As demand grows, it’s essential to invest in technologies like the Ethanol Chiller that deliver consistent results without compromising the bottom line.